The Science of Expiry Dates in Professional Kitchens

Why are expiry dates hard to calculate?

Expiry dates are difficult to calculate because they depend on multiple scientific factors – temperature, time out of refrigeration, handling, humidity and pH – which change with every preparation. Manual calculations lead to inconsistencies and errors. Digital systems like Andy automate expiry dates with precise timing, full traceability and early warnings to avoid risks.

Calculating expiry dates for prepared food seems simple: write down a date, add a few hours or days, label it and move on.

But in professional kitchens, determining accurate expiry dates is one of the most complex and error-prone tasks. Not because teams lack skill, but because the science behind food safety involves multiple variables that change constantly.

Here’s why manual expiry calculations often fail — and how digital systems eliminate that risk entirely.

1. Expiry dates aren’t fixed: they are applied science

The safe life of a prepared product depends on microbiological, chemical and environmental factors. Small variations can change the result:

-

Internal temperature of the food

-

Total time spent in the danger zone (5°C–60°C)

-

Handling and cross-contamination risk

-

Humidity and water activity

-

Ingredient type and pH

-

Cooling and reheating methods

This means two visually identical products can have different expiry dates.

Any attempt to calculate them “by eye” or by using generic rules almost always results in errors, inconsistencies or unnecessary waste.

2. The real issue: operations move faster than precise calculations

During a service rush, nobody has time to manually review:

-

the formula used to calculate expiry dates,

-

the exact time the batch was opened,

-

temperature logs,

-

minutes spent out of refrigeration,

-

the previous rotation of that same product.

Teams are focused on orders, cleaning, prep lists and coordinating stations.

Human memory becomes the system – and that’s a risk.

3. Manual expiry dates create invisible operational errors

The most common problems include:

-

wrong dates or times

-

confusion between “use by” and “consume by”

-

incomplete or unreadable labels

-

inconsistent calculations between team members

-

batches without any record

-

expired items that go unnoticed

The danger is that everything seems correct… until an inspection reveals a gap, or stock loss exposes the mistake.

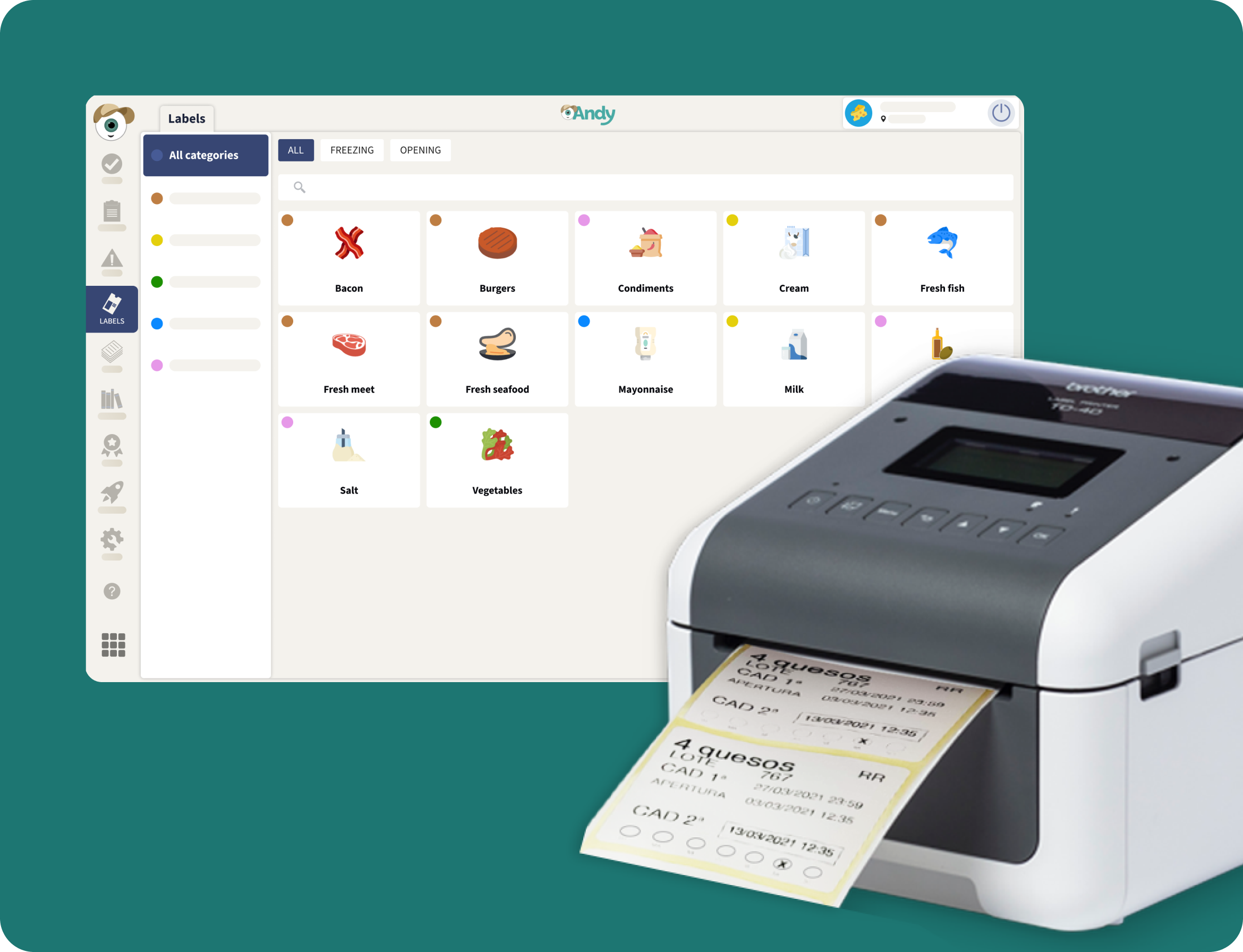

4. The solution: automate expiry dates to eliminate human error

A food labelling digital system like Andy does in milliseconds what no team should calculate during a busy shift:

-

applies the correct shelf-life rules automatically

-

calculates the exact expiry date and time

-

prints accurate, standardised labels

-

links every batch to complete traceability

-

sends alerts before something expires

-

blocks expired products from being used

This removes guesswork entirely and transforms a high-risk task into a fully reliable process.

5. Why accurate expiry dates matter

Getting expiry dates right has a direct impact on:

-

food safety and compliance

-

lower waste and cost savings

-

audit readiness

-

smoother team communication

-

reduced stress during service

-

consistent product quality for customers

The science behind expiry dates is complex.

But managing them doesn’t have to be.

With Andy, assigning accurate expiry dates becomes instant, traceable and error-free – every single time.